Tags: Ceiling Beams, Decorative Wall Panels, Faux Wood Beams, Faux Wood Planks, T&G Ceiling Planks, Tongue and Groove

Did you know that there were more than 700 million household projects worth almost $600 billion alone in 2021? With a figure like that, it’s probably likely that you are considering a home renovation project of your own.

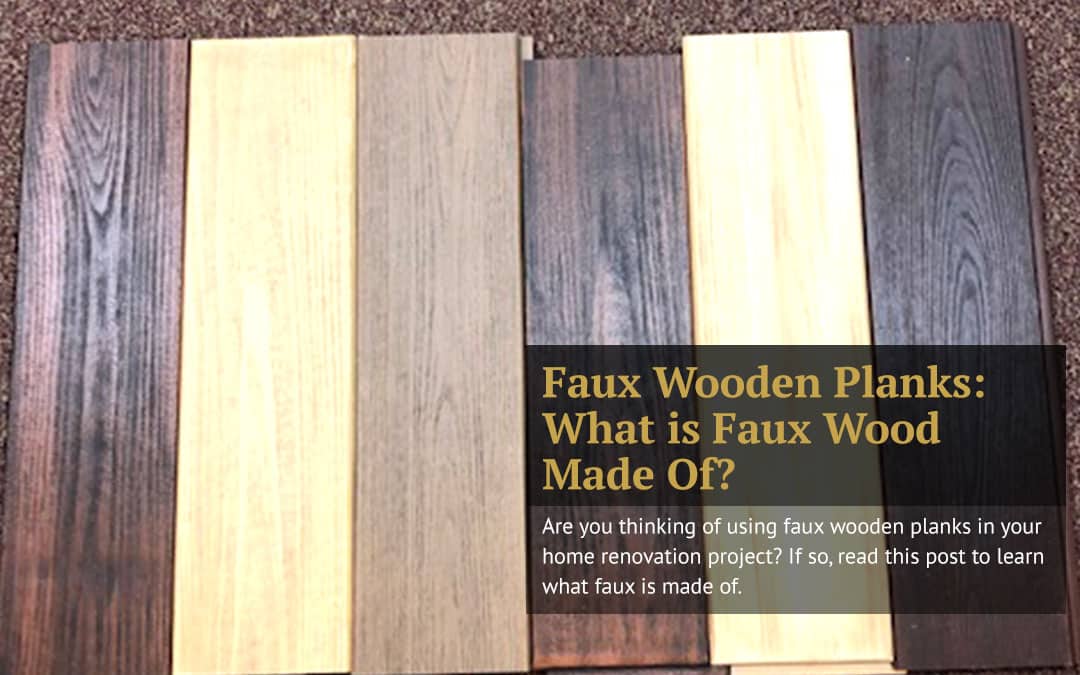

A common renovation project involves installing faux wooden planks for flooring. While faux flooring has advantages over regular wood, you might be asking what it is made of? Read on to find your answers.

What Are Faux Wooden Planks Made Of?

The first type of faux wood is particle board. Production for this type includes binding sawdust and woodchips together with resin and coating to make it more water-resistant.

Hardboard is another faux wood type produced in this manner, just slightly more durable. Because of the increased durability, hardboard is often used in flooring, whereas furnishings are the primary use for particle board.

Veener lumber is a stronger form of faux wood planks. Production encompasses the compression and binding of thin wood strips. It is finally laminated to give a natural appearance.

How Has Faux Wood Improved?

The development of faux wood has improved by moving away from harmful chemicals used in production. While some cheaper forms of faux wooden planks still use formaldehyde, the aforementioned planks types do not. Improvements like these are production builders are now using faux wood on a larger scale.

What Are the Pros and Cons of Faux Wood?

Depending on the type of faux wooden planks, there are pros and cons compared to each other and regular wood plank flooring. The type that is best for you depends on the project.

Cost

As with any project, the cost is always a consideration. Compared to traditional wood plank flooring, faux wood is more affordable. The less durable forms of faux wood tend to be the cheapest.

Moisture Resistance

Particle board is the least resistant to moisture and is not recommended for outdoor settings. If exposed to excessive moisture, particle boards can swell. Both veneer lumber and hardboard are better for handling moisture, especially when they are laminated.

Strength

Veneer lumber is the strongest variety of faux wood, in fact, it compares favorably to traditional wood. Hardboard is stronger and more durable than the closely related particle board.

Durability

While tied to moisture resistance, wooded planks used on flooring must also be able to resist pressure and the constant pounding. Because of its brittle composition, particle board is the most prone to damage and is considered less durable than the other types.

Other Uses For Faux Wood

Because of the improvements in appearance and strength, faux wood is used in more than just flooring. The uses include planks in blinds and beams in ceilings. As with flooring, different colors and finishes are often available.

Are You Ready For Faux Wood?

Now that you know the benefits of faux wood compared to traditional wooden planks, what are you waiting for? There are different types of faux wood to choose from and you should compare the different features. There are even other uses for faux wood.

If you’re ready to begin your next project, contact us for all your faux wood needs.